The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

Release Date:2024-01-20 Click:5426

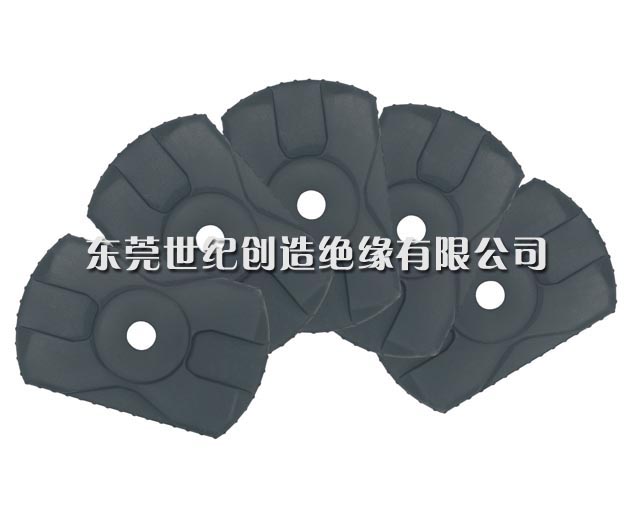

Rubber foam is a base fabric made of rubber closed cell or open cell foam materials made from natural or artificial rubber. Half a century ago, people extensively used this material for sneakers, sports shoes, travel shoes, release shoes, casual shoes, and so on. It has excellent elasticity, good tear resistance, aging resistance, corrosion resistance, electrical insulation and other properties.

The principle of producing rubber sponge through solid rubber foaming is to add foaming agent or co foaming agent to the selected rubber material. At the vulcanization temperature, the foaming agent decomposes and releases gas, which is surrounded by the rubber material to form foam pores, causing the rubber material to expand and form a sponge. The main factors that determine and affect the pore structure of the foam include: the amount of gas generated by the foaming agent, the diffusion rate of gas in the rubber material, the viscosity of the rubber material, and the vulcanization rate. The most critical factors are the matching of the amount of gas generated by the foaming agent, the rate of gas generation, and the vulcanization rate of the rubber material.

The gas generation and decomposition rate of foaming agent refer to the volume of gas released by the complete decomposition of foaming agent per unit mass under standard conditions, measured in mL/g. The decomposition rate of foaming agent refers to the amount of gas released per unit time by the decomposition of a certain mass of foaming agent at a certain temperature. Since the polymer itself does not alter the decomposition mechanism of the foaming agent, it is not necessary to measure the gas evolution of the foaming agent in the polymer. The decomposition rate varies with different types of foaming agents, particle sizes, and temperatures. In general, foaming agents with low decomposition temperatures have a fast decomposition rate; For the same foaming agent, with small particle size and high temperature, its decomposition rate is fast. The gas generation and decomposition rate of foaming agents affect the size and structure of foam pores, with high gas generation, fast decomposition rate, large formed foam pores, and a high probability of opening pores. Analysis of the matching between the decomposition rate of foaming agents and the vulcanization rate of rubber materials.

Next article:How to distinguish the quality of rubber foam strips?

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization